Company Rolls Out Second Lower-Carbon Product in 2021 Following its Introduction of Lower-Carbon Caustic Soda in February 2021.

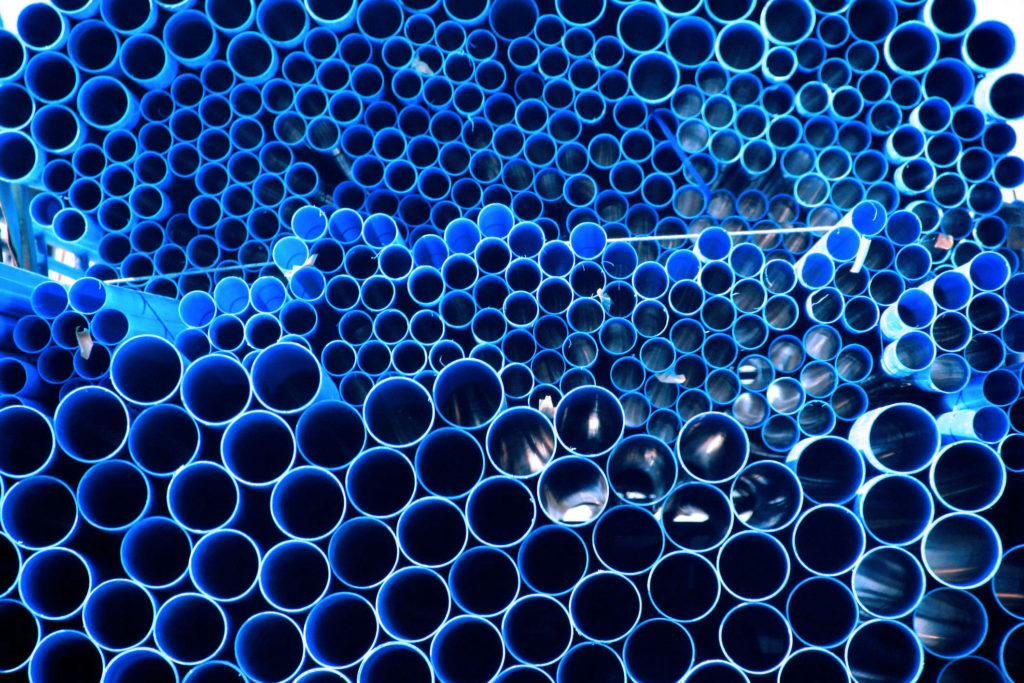

Westlake Chemical Corporation (NYSE: WLK) today announced its Vinnolit subsidiary in Germany launched GreenVin® Polyvinyl Chloride (PVC), a lower-carbon alternative PVC, which is one of the most widely utilized plastics in the construction, automotive and medical sectors.

“Market demand for lower-carbon plastics and materials is rising rapidly as more customers are seeking ways to reduce their carbon footprints and meet their sustainability goals,” said Vinnolit Managing Director Dr. Karl-Martin Schellerer. “GreenVin® PVC performs as well as traditional PVC while offering a more climate-friendly product that our customers can feel good about using. This product and the entire GreenVin® product line are part of our overall commitment to meeting society’s needs and enabling a better future.”

The introduction of GreenVin® PVC follows the market launch of GreenVin® caustic soda earlier this year, with the product line expected to extend into the company’s vinyl chloride and hydrogen products in the future. Caustic soda is an essential ingredient in the production of many materials, including detergents, construction materials, pulp and paper, pharmaceuticals and water treatment products.

The Vinnolit GreenVin® brand is based on high-quality renewable energy certificates (Guarantees of Origin / GOs) associated with the production of the lower-carbon PVC and caustic soda. Depending on the PVC type, the carbon-dioxide savings with GreenVin® PVC are about 25% compared to conventionally produced Vinnolit PVC. The respective carbon footprint for the entire product portfolio was calculated by Sustainable AG in accordance with the ISO 14067 standard. Review and certification are carried out by TÜV Rheinland.

Westlake recently released its 2020 ESG Report, Essential Products, Critical Innovations, which provides details on its ESG goals and achievements for its operations, safety, products and people, and includes information on lower-carbon product development and more sustainable manufacturing. Procuring green power – in addition to the continuous improvement of the energy efficiency of the production processes – is a step toward achieving carbon-neutral PVC supply. These efforts also support the energy transition and the European Green Deal. In addition, Vinnolit is working with partners to also offer bio-attributed PVC, based on bio-ethylene.

“With GreenVin®, we are working to make the entire Vinnolit product portfolio, including PVC, more environmentally friendly and sustainable,” Schellerer added. “At Westlake and Vinnolit, we are proud to be doing our part for a stronger industry and a sustainable future.”

Media Relations:

Dr. Oliver Mieden, Head of Environmental Affairs & Corporate Communications

Vinnolit GmbH & Co. KG, Carl-Zeiss-Ring 25, 85737 Ismaning, Germany

Tel.: +49 89 96103-282, E-Mail: oliver.mieden@westlakevinnolit.com

Andrea Walter, Public Relations Officer

Vinnolit GmbH & Co. KG, Carl-Zeiss-Ring 25, 85737 Ismaning, Germany

Tel.: +49 89 96103-240, E-Mail: andrea.walter@westlakevinnolit.com